You call and no one responds. You email and no one reads it.

You state your urgency, but urgency isn't given.

Whether you're dealing with an aircraft component repair vendor or even the barber down the street, you want to be heard, understood. Am I right? Or have I fallen off somewhere?

With aircraft component repair vendors, there are 5 unwritten laws you must follow. Each of these laws must be followed, you can't pick one and not the other.

If you follow these laws, your life will seem easier, the relationships with your repair vendors will be strong and your bottom line will begin to rise.

So what are we waiting for?

Here are the 5 laws to follow with choosing an aircraft component repair vendor:

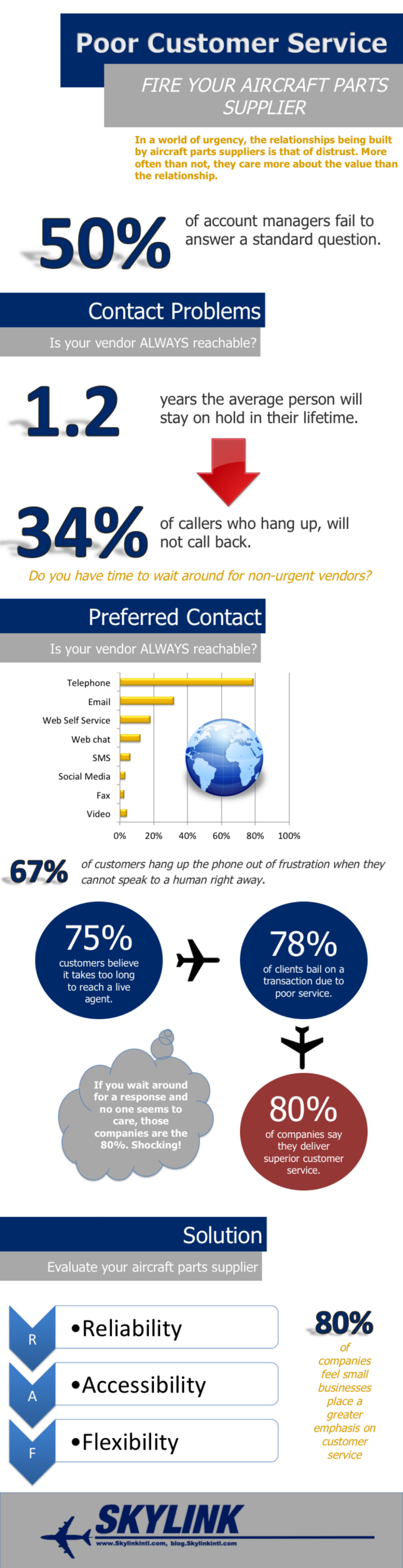

1) Communication

The law of communication allows both parties to be on the same page. Communication creates a win/win relationship. Do they communicate effectively?

2) Organization

The law of organization is how the relationship is molded. It's how you and your vendor understand one another. Are they organized?

3) History

The law of history gives you great insight on your repair management partners past. Where have they been, where are they going and how do you fit in the picture. Do they have a history?

4) Personality

The law of personality goes deep into the organization. Once you know their personality, you'll know their intentions. Do they have a personality?

5) Flexibility

The law of flexibility shows if thry're agile or motionless dictated by corporate red tape. Agile is always good.

These laws give you a deep understanding of your aircraft component repair vendor and should be the backbone of your decision making process. They will guide you to make rational, calculated decisions to work with a vendor that understands and cares about your unique operation.

Have you missed the other 3 parts of this aircraft repair management series?

Series 1: Does Aircraft Component Repair Keep You Up At Night? Series 2: 7 Ways Repair Management Can Simplify Your Life Series 3: 12 Point Checklist To Reap The Benefits Of Understanding Your Aircraft Repair Management Partner

We would love to hear from you. Do you follow these laws? Either send us an email or respond in the comment section below.