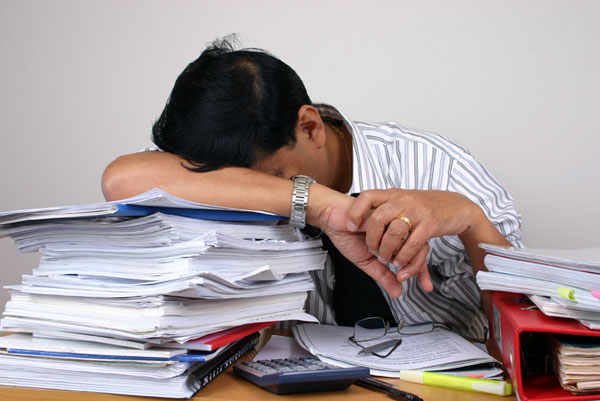

Do you feel overwhelmed having to manage your aircraft component repair processes? This is understandable as each MRO has its way of communicating information to you, not to mention the freight costs associated with shipping to various facilities. From exaggerated mark-ups on piece parts to inflated labor rates, this can easily become a nightmare.

Just recently our repair manager dealt with an issue that I just didn't understand. One of our avionic units was sent to an aircraft undergoing maintenance to be installed. After installation, there seemed to be an intermittent issue with the avionic so we had it overnighted back to the MRO who originally performed the work. Warranty was granted. 120 days later, after having to supply another unit to fulfill the aircraft maintenance requirement the MRO sent a bill for $400+ for labor. We kindly declined this bill and after many discussions the shop decided to waive this fee. This was sneaky and if we weren't paying attention to the original warranty granted, we would have paid this. Needless to say, this MRO is no longer on our approved vendor list for aircraft component repair.

How can you avoid stressing over such issues?

By dealing with an organization who deals with repairs on a daily basis, there are key benefits they possess that you may not.

Below are 4 reason you should be using a repair management program:

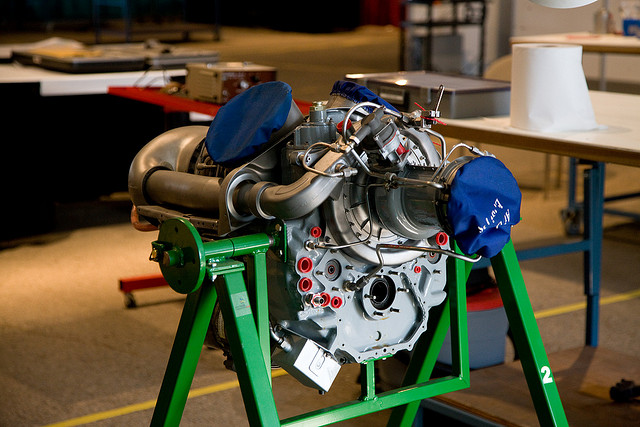

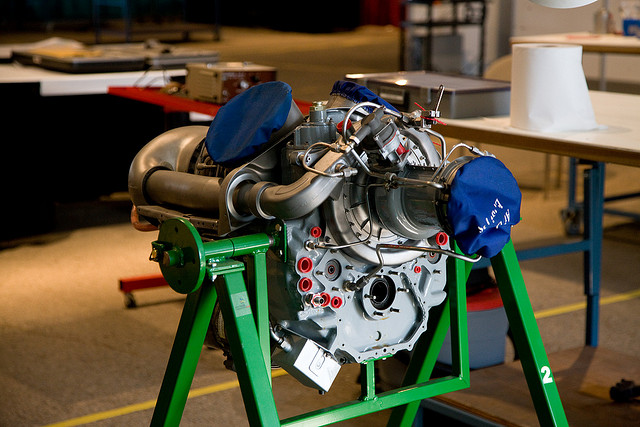

1) Minimize Repair Cost

Outsourcing to one vendor that can accommodate your aircraft component repair needs can reduce your overall cost per part. Do you stock piece parts in preparation for component repairs? Do you have replacement units that can be used if your other unit goes BER? What about as removed units that can be used for piece parts for another unit undergoing repair? If the answer is no, then a repair management program may be right for you.

Why not just send all your units to one MRO? This can be answered in 3 words…KEEPING THEM HONEST. MRO facilities typically have ratings for certain repairs and can't perform the vast aircraft component repair services you're looking for. When an MRO get's an influx of repairs they can start to drag their feet and become overwhelmed and disengaged. They will also markup piece parts to make it seem as through your unit is more expensive to repair than it should be…increasing their margins.

By utilizing a repair management program, you have the ability to focus on your core competencies while a reputable company manages your repairs. In doing so they will ensure the MRO is staying honest by remaining actively engaged with them, providing their own piece parts at un-inflated rates and making sure they're not telling you one thing and doing another.

2) Minimize Shipping Cost

Many airlines deal with the overwhelming costs of shipping items for repairs, primarily throughout the United States. It's not cost effective to ship repairs from overseas to different MRO's all across the continental United States which spans 3,400 miles East to West.

You can reduce shipping cost by consolidating shipments with your repair management program provider. They should also have a network of shipping companies in which they do frequent business with, at discounted rates.

3) Leveraging High Volume Repairs

During your aircraft maintenance you can forecast your repair needs depending on what check you're going through. If any unplanned issue arise you can then take advantage of your contingency plans but just utilizing what you have to repair may not be enough.

For example, lets say you need 5 undercarriages overhauled and made compliant with the most recent service bulletin. This will cost you roughly $6,000 per undercarriage if you send this directly to the MRO. Now, if you utilize a repair management program your 5 undercarriages may be 5 of 20 undercarriages your repair management service provider is repairing for their airline clients. This gives them significant bargaining power over the MRO. They may have negotiated a flat rate overhaul based on their volume and save you $1,000 per undercarriage, $5,000 in total.

You may have many components needed for repair in support of your aircraft maintenance, but if you combine this in addition to what the repair management program is doing for other airlines, bargaining power can increase and substantially lower your overall repair costs.

4) Established Relationships

Repair management programs have built decades of relationships with hundreds of MROs and OEMs.

While many MROs won't allow you to provide your own piece parts which can drastically increase the cost due to inflated markups, a successful repair management program has experience providing their own piece parts, numerous airline client's parts, and other vendor parts to reduce the overall cost of the aircraft component repair process.

With a successful repair management program, relationships have been built minimizing your resource consumption by utilizing the available resources through such a program. This will effectively reduce your overall cost and downtime.

The procurement of spares and the oversight of aircraft maintenance and aircraft component repair for the daily operation of an airline is often very complex and time consuming. Most of the time decisions have to be processed to upper level management which takes further time and money. Why not leave these decisions to one company?

Utilizing a repair management program will not only save you money, but also endless headaches. Repair management combined with rotable support can be a good strategy to relinquish you from the stress and miscommunication associated with repair companies.

What deciding factor would make you choose a repair management program? Comment below.

scheduled our truck to pick the units up but we got a call that the thrust reversers we’re improperly crated and they had to bump the pick-up. It took 2 additional days to get them into transit.

scheduled our truck to pick the units up but we got a call that the thrust reversers we’re improperly crated and they had to bump the pick-up. It took 2 additional days to get them into transit.