Not long ago, we walked through a client's warehouse.

Prime shelf space.

Perfect climate control.

State-of-the-art racking.

And row after row of parts collecting dust like museum pieces. The procurement manager shrugged:

"That's just how it is."

No. That's how money dies.

Your surplus inventory isn't just sitting there.

It's actively burning cash.

Every rotable gathering dust represents tied-up capital.

Every expendable past its prime takes space from parts you actually need.

That "just in case" mentality?

It's costing you more than an AOG situation ever could.

The Hidden Cost of Surplus

Let's get brutally honest about what surplus really costs.

Storage fees compound monthly.

Insurance premiums climb with inventory value.

Staff time gets wasted counting parts nobody uses.

Meanwhile, your CFO wonders why working capital looks like a black hole.

Think about it like this: A single nose wheel assembly taking up shelf space for 18 months costs more in storage than its depreciated value.

You're literally paying to lose money.

And that's before we talk about obsolescence risk, certification expiration, or the simple fact that aerospace technology moves forward while your parts sit still.

Real Talk: Why Buyers Don't Sell

I get it. You're not hoarding on purpose.

Maybe you're afraid you'll need that part the moment you sell it. Classic Murphy's Law thinking.

Or perhaps dealing with surplus got buried under seventeen other priorities.

Sometimes it's pure bureaucratic paralysis—too many approvals, too much paperwork, too little time.

Here's what nobody admits: Most procurement teams don't sell surplus because they don't know where to start. The market feels opaque.

Pricing seems like guesswork.

And honestly? The constant haggling with other end users, brokers, and the uncontrollable daily RFQs.

How To Actually Move Surplus Aircraft Parts

How do you actually turn that excess into value?

It starts with taking deliberate steps, the same way you'd follow a checklist before pushback.

1/ Audit What’s Actually Moving

Don’t trust memory—trust data.

Pull 12–18 months of transaction history and rank your parts by turns.

Which part numbers moved more than three times? Which haven’t moved once? That’s your starting point.

If you skip this step, you’ll keep protecting “someday” stock that’s quietly killing your budget.

2/ Spot the Real Value

Not all surplus aircraft parts are created equal.

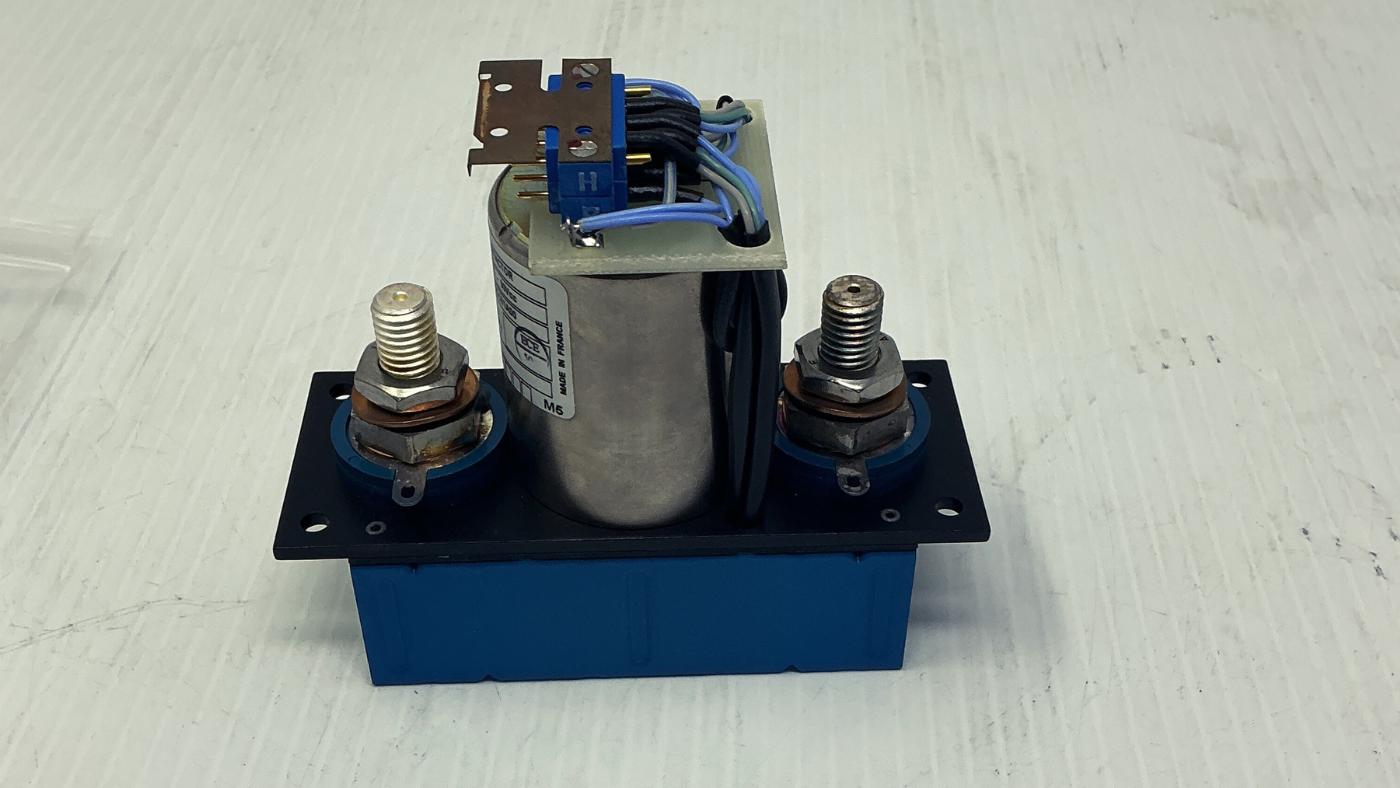

Start with your high usage material: rotables with complete trace documentation and recent 8130s.

Then hit expendables for current fleet types—737NG, A320, and ATR parts move fast.

High-value avionics with remaining warranty? Gold.

That obscure part for a DC-9? Save it for never.

Create three buckets: hot sellers, steady movers, and "good luck with that."

Focus your energy where the market actually exists.

3/ Get a Partner Who Knows What Moves

You're not a parts dealer—and you shouldn't have to be.

Find a trusted aircraft part consignment partner who breathes this market daily.

They should know instantly that your APU starter has demand in Southeast Asia.

That your brake assemblies are hot in cargo operations but cold in passenger markets.

The right partner turns your guesswork into strategy. They've got the buyer network you don't have time to build.

4/ Lead With Full Transparency

Here's where deals die: hidden surprises.

Be upfront about everything.

Part has minor corrosion? Say it.

Paperwork is incomplete? Disclose it.

Previous repair history? Document it.

Include clear photos—not artistic angles that hide flaws.

List your actual certifications, not what you think you have.

Buyers can smell BS from across the hangar, and one bad deal ruins ten future ones.

Transparency isn't just ethical—it's profitable.

The Surplus Sale Mindset Shift

Stop thinking like a collector. Start thinking like a CFO.

Every surplus part represents frozen capital that could fund your next critical purchase.

That shelf space could hold fast-moving inventory.

Those storage costs could improve your bottom line.

Smart operators treat surplus sales like preventive maintenance—regular, systematic, non-negotiable.

They understand that moving old inventory isn't admitting defeat. It's operational excellence.

Your Move

Your warehouse shouldn't be an aircraft parts cemetery.

Every square foot costs money. Every surplus part is an opportunity wearing a disguise.

The question isn't whether to clear surplus. It's how much money you're willing to leave on the shelf.

Ready to turn your surplus into strategy?

Schedule a call and we'll review your inventory—no fluff, just actionable solutions that move parts and free up capital.