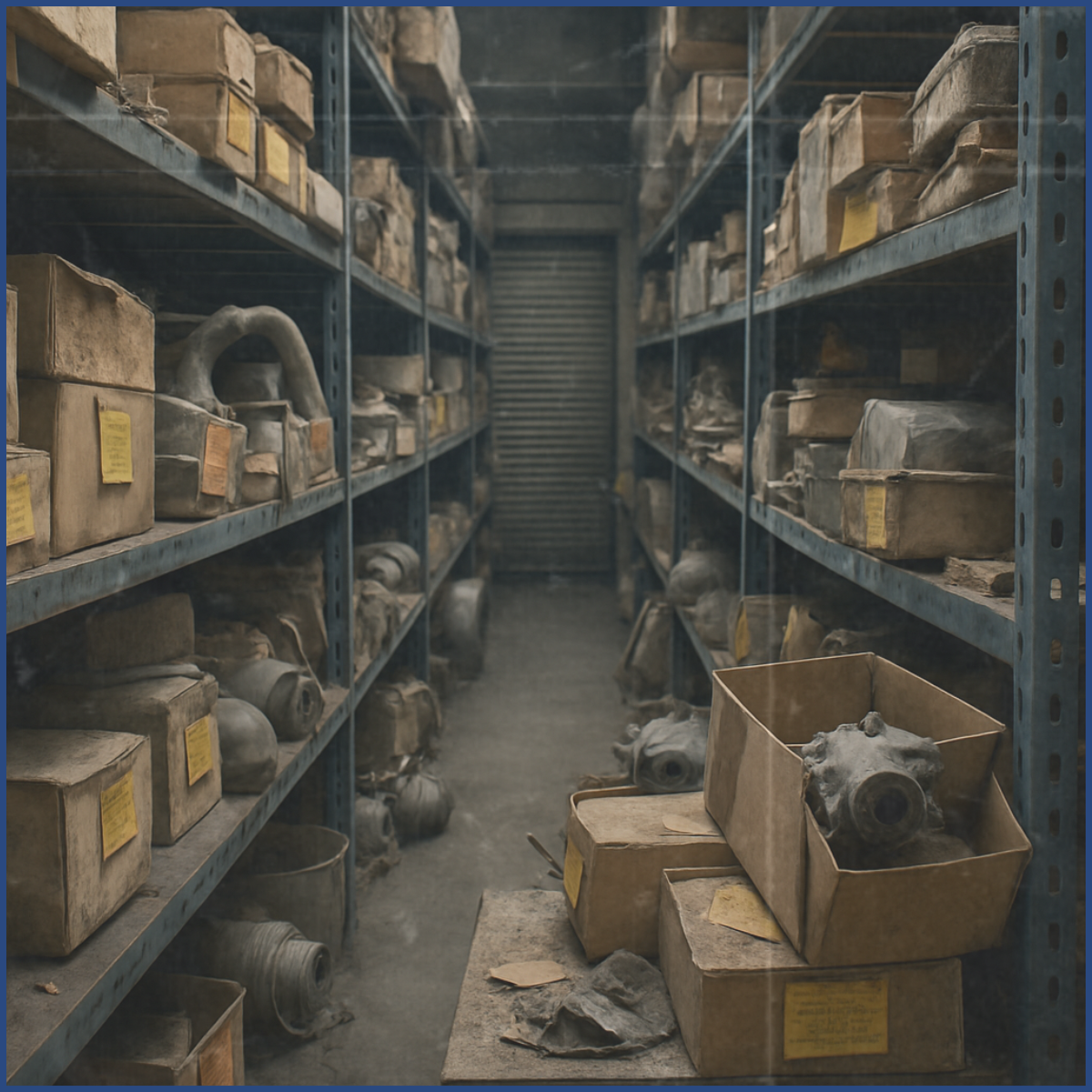

Recently, I watched a procurement manager stare at rows of surplus inventory worth millions, gathering dust in their warehouse—parts that hadn't moved in 12+ months.

Here's the brutal truth about surplus inventory: it's not an asset (unless that's your business 🙋♂️).

It's a liability that bleeds your budget dry through storage costs, insurance, and opportunity costs.

Every day those parts sit unused, you're paying for warehouse space, tracking systems, and insurance coverage on inventory that generates zero revenue.

Meanwhile, your cash sits trapped on shelves instead of funding your operation.

We once worked with a regional carrier whose parts manager proudly showed us their "well-organized" inventory.

Row after row of perfectly catalogued components—$8 million worth.

When we asked how much revenue those parts generated last quarter, the silence was deafening.

They were spending $40,000 monthly on warehouse space for parts that hadn't moved in years.

That's nearly half a million dollars annually to store inventory that wasn't working for them.

Surplus inventory is the silent killer of capital for operators and MROs.

But what if you could turn those idle parts into a revenue engine—without the headaches of discount sales or slow-as-molasses brokers?

Enter: Strategic Consignment.

Here's why smart operators and airlines are consigning surplus with partners like Skylink—and how it's changing the game:

The 5 Massive Benefits of Consigning Your Surplus Aircraft Part Inventory to an Asset Manager

1. Instant Cash Flow Without the Storage Headaches

Consignment turns your surplus into working capital without the nightmare of managing individual sales.

Instead of paying warehouse costs while hoping for buyers (which likely isn’t your primary mode of business), you transfer inventory to specialists who handle everything—storage, marketing, and sales—while you collect payments as parts move.

The math is simple: stop paying to store parts and start getting paid when they sell, and invest your time in your core business.

One client freed up $200,000 in annual storage costs by consigning a small lot of surplus inventory and then reinvested that capital in stocking high-turnover line maintenance materials.

2. Zero Risk, Maximum Recovery Value

Here's what most people miss about consignment: you retain ownership until sale.

No upfront costs.

No minimum commitments.

No risk of getting lowballed by bulk buyers who know you're desperate to clear space.

Quality consignment partners use market intelligence to price competitively while maximizing your return.

They know which parts are in demand, when prices peak, and how to reach buyers you'd never find on your own.

3. Professional Marketing That Actually Moves Parts

Your procurement team excels at buying parts, not selling them.

Consignment partners live in the sales world—they have buyer networks, marketing systems, and industry connections that transform dormant inventory into closed deals.

While you focus on keeping aircraft flying, specialists handle photography, listings, negotiations, and the entire sales process.

It's like having a dedicated sales team without the overhead.

4. Reduce Operational Drag and Warehouse Chaos

Surplus is sneaky.

It looks harmless until your warehouse crew can't find space for critical incoming material…or wastes 20 minutes re-verifying the trace on a part no one has touched in two years.

Every idle unit costs labor, space, insurance, cycle counts, and energy. That's a tax on your team's time and performance.

Consigning surplus is like a spring cleaning for operations.

It unclogs the arteries of your warehouse.

It tightens your inventory audits.

It lets your operations team focus on what actually supports the line.

5. Turn "Dead" Inventory Into Unexpected Profit

Some parts you've written off—mentally and financially—still have demand.

Aircraft age differently in different regions. What's obsolete in your fleet might be gold to a Caribbean turboprop operator or a South American low-cost carrier.

Consignment gives that material a second life.

Instead of scrapping it or hoping someone bites on a steep discount, you capture real value—often far more than you expect—by matching those parts with global demand.

Even a modest recovery is better than another year of depreciation and space costs.

Surplus inventory consignment isn't just about clearing warehouse space—it's about optimizing your entire parts management strategy.

You convert dead inventory into working capital, eliminate storage costs, and gain market intelligence that improves future procurement decisions.

The question isn't whether you should consign surplus inventory.

It's whether you can afford to keep paying costs on parts that could be generating revenue instead.

Ready to Offload Your Inventory Burden?

Start with just one question:

What's the ROI on keeping this part in storage for another year?

If the answer is zero—or worse—it's time to flip the model.

Run an internal surplus audit.

Pick the part numbers gathering dust.

Start a conversation with a trusted consignment partner.

If it’s anything less than “positive cash flow”… let’s talk.

Even if you’re not ready to consign, we’ll happily run a free surplus audit to help you identify the low-hanging fruit. You might be sitting on $50K+ in recoverable capital—and not even know it.

Don't wait until you're forced to act.

Move now—and get your capital, space, and sanity back.