Your last RFQ might have saved you $500 per part and cost you $50,000 in downtime.

Here's the brutal truth about aircraft parts procurement: most purchasing teams are playing a dangerous game of price roulette.

They fire off RFQs like scatter shots, collect quotes like baseball cards, and pick the lowest number, thinking they've won.

Then reality hits.

The "bargain" part shows up late.

The trace documentation looks like it was written by a third-grader.

The vendor goes silent when you need support.

Your aircraft sits grounded while you scramble for a replacement supplier.

The Real Cost of Fast and Cheap RFQs

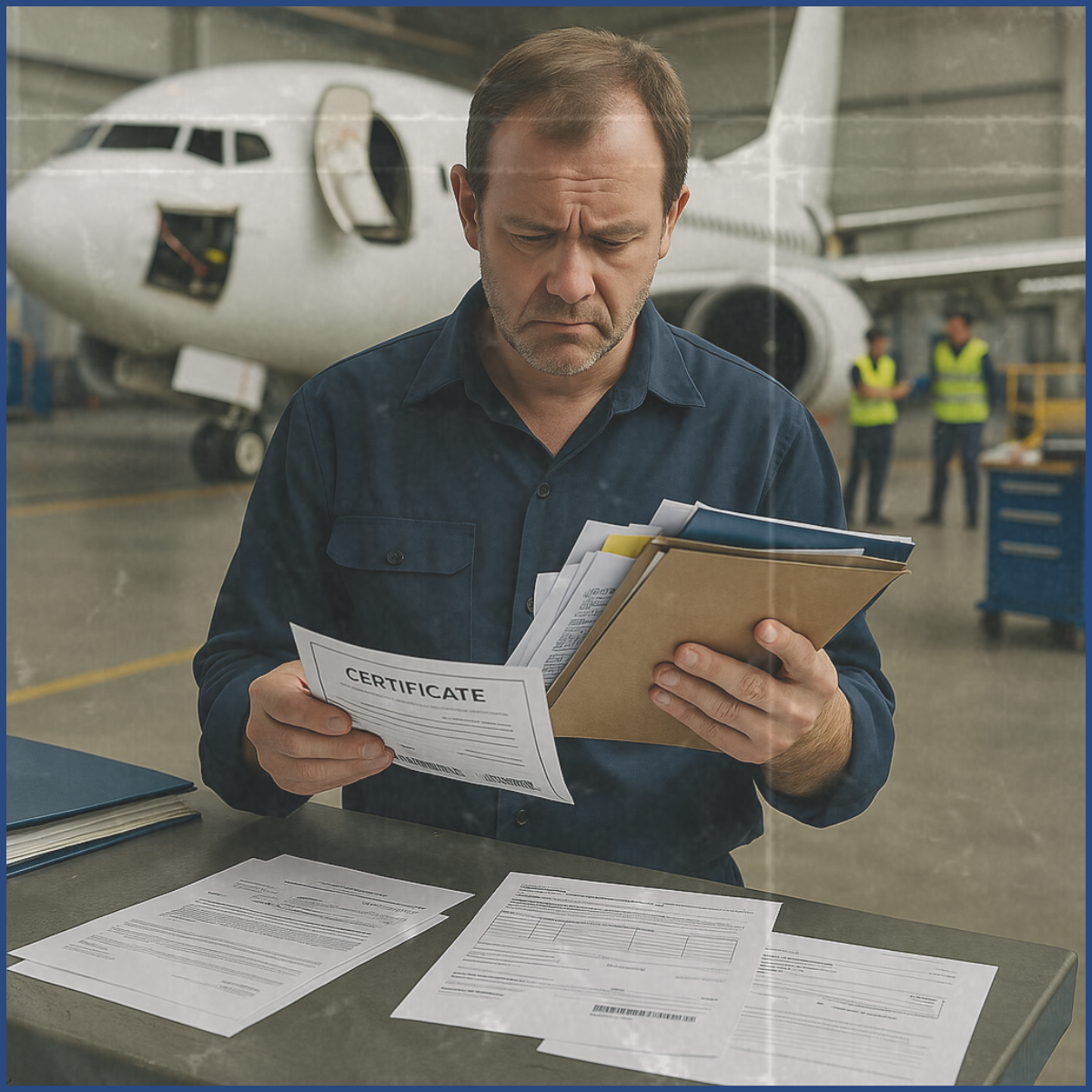

Last month, I watched a supply chain manager celebrate a 15% cost savings on landing gear components.

Three weeks later, that same manager was explaining to his VP why their A320 was sitting in maintenance for an extra four days because the "cost-effective" vendor delivered parts without proper certification.

The math was ugly: $500 saved per part. Tens of thousands of dollars in lost revenue. Four days grounded.

You do the math.

This is what happens when speed trumps strategy.

When price becomes the only metric that matters. When RFQs become a race to the bottom instead of a search for value.

How Fast RFQs Create Slow Deliveries

Your rushed RFQ process is creating its own problems.

Here's how:

1/ Incomplete Requirements Lead to Incomplete Solutions

When you blast out an RFQ with minimal specifications, you're asking vendors to guess what you really need.

Some will guess conservatively and quote high to cover unknowns. Others will quote low and hit you with change orders later.

Neither scenario serves your aircraft or your budget.

2/ Poor Communication Creates Poor Partners

An RFQ that reads "Need part ASAP, send best price" tells quality vendors everything they need to know about how you operate.

It signals that you're transactional, not partnership-minded.

The vendors who want to build long-term relationships? They'll either pass or quote defensively.

3/ Volume Thinking Defeats Value Creation

Sending the same RFQ to 100 vendors feels productive.

In reality, you're training the market to compete on price alone.

Quality suppliers start to wonder if they're wasting time preparing detailed proposals for buyers who only care about the bottom line.

The Hidden Cost of Poor Trace Communication

Here's where the real money gets lost: documentation disasters.

Every aircraft part needs a paper trail that proves its airworthiness.

When your RFQ doesn't clearly specify trace requirements, you're setting up for expensive surprises:

Certificates that don't match the part numbers

Missing test reports that ground your aircraft

Trace documents that arrive days after the parts

Documentation that doesn't meet your airline's standards

I've seen maintenance teams spend more on express shipping corrected paperwork than they saved on the original "cheap" parts.

Building RFQs That Attract Better Vendors

Smart procurement starts with smart requests. Here's how to structure RFQs that bring quality vendors to your door:

A. Lead with Context, Not Just Part Numbers

Instead of: "Need PN 123456789, send quote."

Try: "Line maintenance operation for regional carrier, need reliable supplier for recurring brake components, looking for 60-day terms and consistent delivery windows."

Quality vendors want to understand your operation. Give them enough context to propose real solutions.

B. Specify Your Complete Requirements Upfront

Include everything that matters:

Delivery location and preferred timing

Trace documentation standards

Payment terms you can actually meet

Support expectations beyond delivery

Volume projections for planning purposes

C. Ask the Right Questions

Don't just ask for price. Ask for:

Average delivery time for this part number

Trace document turnaround time

Support availability for urgent requirements

References from similar operations

Inventory levels and replenishment schedules

Why Vendor Reliability Starts with How You Prepare

Your RFQ process is a job interview. You're not just evaluating vendors—they're evaluating you.

Quality suppliers have options.

They choose to work with customers who demonstrate professionalism, clear communication, and realistic expectations.

When your RFQ process is sloppy, rushed, or price-obsessed, you're telling quality vendors to look elsewhere.

The vendors who respond to poorly written RFQs?

They're often the ones who have time to respond because their existing customers aren't keeping them busy.

The Partnership Principle: Why Material Partners Matter

Here's what separates successful procurement teams from struggling ones: they think partnerships, not transactions.

A good material partner becomes an extension of your inventory management.

They know your aircraft types, understand your maintenance cycles, and anticipate your needs.

They stock parts before you need them.

They expedite when emergencies hit.

They solve problems instead of creating them.

This doesn't happen with the always lowest bidder who's seeing your part number for the first time.

Building Your Strategic RFQ Process

Transform your procurement with these strategic steps:

STEP 1: Create Vendor Tiers

Tier 1: Proven partners for critical components

Tier 2: Qualified suppliers for standard requirements

Tier 3: Emergency sources when needed

STEP 2: Develop Standard RFQ Templates

Critical AOG requirements (speed over cost)

Planned maintenance needs (value over price)

Bulk/forward buy opportunities (volume discounts)

STEP 3: Measure What Matters

Track vendor performance on:

On-time delivery rates

Documentation accuracy

Problem resolution speed

Total cost of ownership (not just unit price)

Your Next Move

Stop playing procurement roulette with your aircraft readiness.

Your competition is learning that the lowest quote rarely equals the lowest total cost.

Smart maintenance operations are building supplier relationships that deliver predictable results, not just competitive prices.

Ready to build an RFQ process that attracts quality partners instead of price chasers?

Contact Skylink's supply chain experts and discover how strategic procurement can transform your maintenance operation.

P.S. - The next time you're tempted to pick the lowest quote, ask yourself: "What's the real cost if this supplier fails?" Your aircraft's uptime depends on the answer.