You're going nuts. You spend a ton of time processing, organizing and following up with aircraft material purchases. It's all you do...all day long. It's time consuming. It costs money. It's not efficient. Yet, it has to get done.

So what are you going to do? The first thing is to take a step back. Look at the big picture. What’s your biggest underlying problem? Most airlines and MROs get so caught up in what they have to do or what they have to resolve in the day and they forget the most important part of their operation…efficiency.

This is the catalyst that will save you a ton of money.

You’re spending To Much money on administration

Do you know how much it cost to process a purchase order?

Think long and hard about everything that needs to happen from when maintenance sends you a requisition request to the time the order is received. Every time you process a PO, it costs your operation between $50 and $200. Charles Dominick, at Next level Purchasing, laid out some great statistics:

- A 2006 report from APCQ found that the cost of a purchase order differed depending on the capabilities of the procurement department on a continuum from bottom performer to top performer. This report indicated that the cost of a purchase order ranged from $35.88 to $506.52.

- A 1994 study by the Environmental Protection Agency on its own processes revealed that some of its procurement officials had estimated the cost of a purchase order to be as high as $300, but published a conservative estimate of $94.20 per PO.

- The Supply Management Handbook says “it often costs organizations more than $100 in administrative expenses to generate a purchase order” and that “in many firms, the cost of managing and generating a purchase order can exceed $200 per transaction.”

- CAPS Research indicates that the cost per purchase order varies by industry, from $59 in industrial manufacturing to a whopping $741 in the petroleum industry with the average being $217.

This doesn’t mean you stop purchasing all together. That would be silly. But the reason to understand the cost of a purchase order is to drive efficiency. That's why I’m a huge proponent of a vendor managed inventory as it cuts your administration costs down significantly.

Dealing with unreliable suppliers

Unreliability is a problem. You send a PO to your supplier and you do not get a reply or an order status update. It feels like it would be easier to assemble an aircraft. Or they cancel POs. I’m sure you’ve heard the excuses “we no longer have stock”, “I didn’t quote you that”, “The unit went BER.” Some of these excuses are true. But often they’re thrown around and it’s hard to know.

It’s frustrating. The end result is you wasting time and money.

This is where trust and a total cost of ownership mentality comes in.

Each airline and MRO operation is different, obviously. Some are really good at looking at the total cost of ownership and the risk of unreliability despite an “attractive” price. Supply Chain Brain wrote an excellent article mentioning “The more a company sources from distant, low-cost lands where financial transparency, operating visibility and reliable logistics are practically unknown, the risk of serious supply chain disruptions increases geometrically.”

I find that this is not just the case in “low-cost lands.” It’s very prevalent in the Unites States, Europe and elsewhere. I’ve had countless issues of new, unreliable companies who always cause problems and they’ve been located in Miami, FL. Unreliability is everywhere.

To fix your unreliable supplier problem, build a deep relationship with a key material partner. Test them and make sure it’s the right fit. You’ll know when you’ve found the right partner. You’ll get a feeling of peace and understanding that when you need anything, they’ve got you covered.

Increasing and unpredictable lead times

One of the biggest issues we hear about is lead times (TAT). And rightfully so. When an order goes beyond what you were quoted it disrupts your operation. It get’s even worse when you’re urgent. With our aviation world there’s many factors that play into these extended lead times.

Here’s just a few:

- A rotable needs more repair work and piece parts to complete the overhaul, which extends the lead time.

- Piece parts are obsolete or scarce.

- OEMs are in no rush to ship replacement parts.

- OEMs are not committed to their distribution lead times and continue to push back their production dates.

- Repair stations are slow and overpromise and under deliver.

- Suppliers quote you a lower lead time to get the order when they know exactly how long it’ll take.

- A unit goes BER and a replacement is needed.

There are many reasons for TATs going beyond the due date. All of which are an excuse. And don’t worry, we’re not hidden from this either. But the goal is to come up with a better way. We have a preferred vendor system we live by. I also encourage airlines and MROs to take a step back and think of reliability and TATs as a big picture.

Who’s someone you can count on for all your rotables, expendables and consumables with a track record or reliability? Do you even have one?

Another solution is know what your high consumption items are and utilizing a just in time strategy. With this strategy you’ll have enough stock for the foreseeable future. As you deplete the inventory it’ll be auto replenished. Simple, right?

Increasing costs and your total cost of ownership

No one likes increasing costs. It puts pressure on your operation.

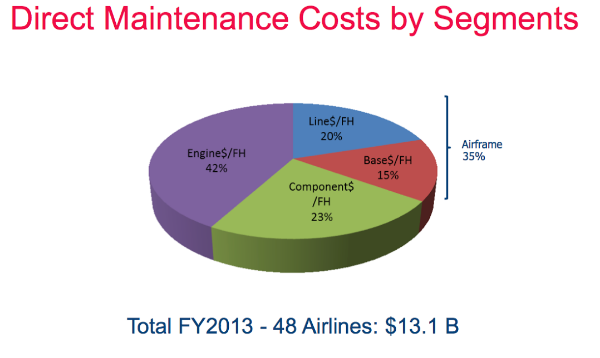

According to IATA, airlines spend an average of $1,063 per flight hour on direct maintenance costs.

But what this figure doesn’t tell you is how much your daily processes and supply chain habits are leaking money. Let me give you an example. Most purchasers look at the direct cost of a component whether it be an aircraft rotable, consumable, or expendable. Most procurement professionals overlook all of the other cost associated with their purchasing activities.

A $10,000 unit may cost you 5 - 15% in shipping, $100 in processing activities (per PO), and if it’s for stock roughly 20% of the component cost is your yearly holding cost. So a $10,000 component will cost you $10,600 if you install it immediately, unless you have to expedite. If you hold this component in your inventory it’ll cost you $12,600 and an additional $2,000 per year thereafter.

Here are some quick fixes to help you reduce your costs and total cost of ownership:

- Cut down on the amount of POs you send. Work with a trusted partner and $ave by consolidating. If you can process a PO with all the rotables, expendables and consumables you need and consolidate the shipment…huge savings.

- Pay careful attention of how you’re shipping. Consolidated your non-urgent items.

- Automate the delivery of your high usage expendables and consumables. A vendor managed inventory is a great strategy.

- 39% of your material needs is for rotables, outsource your inventory.

- Stock your As Removed inventory at your repair partners facility. You’ll reduce processing time, inventory costs, and you’re rotable cycle times will be shorter.

Increasing Aircraft On Ground (AOG) Situations

AOGs are your arch nemesis. You despise the name. Yet, you know they’ll happen and you can’t hide.

It cost airlines approximately $42.83 per minute on the ground (excluding fuel burn). Most people want to talk about the pure cost, yet lost revenue goes ignored by those who report on it. When you factor in the cost and the lost revenue, the opportunity costs increase exponentially. That’s not to mention all the time and money you spend to resolve the AOG.

There’s been numerous times where I’ve seen an airline customer spend too much money to resolve an AOG for a high consumption expendable. This is purely a planning mistake. Here’s an airlines perspective on AOGs.

To resolve AOGs and avoid having to carry excess inventory it all starts with planning and putting a strategy in place. For rotables, a pooling or PBH agreement will work as long as you structure it to meet your operational needs. It must be a win / win relationship. For expendables and consumables a vendor managed inventory for high consumption items is great…and really easy to implement.