Pros & Cons: Time and Material Aircraft Part Repairs

You have a pile of repair orders on your desk. They sit, waiting for you to take action. Do you approve or deny them? It’s a constant price and lead time battle.

With your aged fleet, time and material aircraft part repairs is the best strategy for you. It gives you more flexibility. It’s the shirt that fits nice. It’s not too tight where it's choking you or too loose making you look sloppy.

When you adopt a time and material repair strategy, here’s some of the pros and cons to look out for.

[Tweet "The pros and cons to look out for when you adopt a time and material repair strategy"]

Let’ start with the cons…

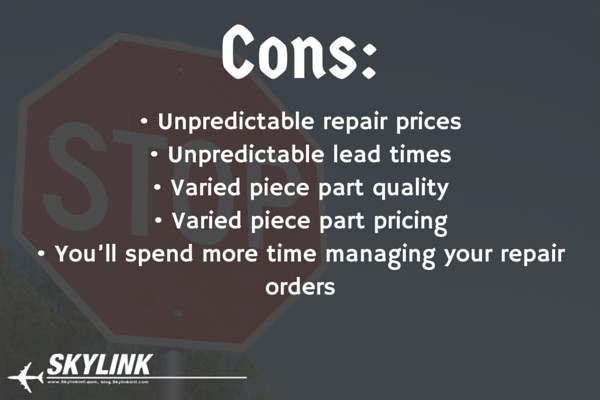

Cons for an aircraft part time and material repair strategy

As with any decision, you must always consider your downside, or simply put, the cons.

Here’s some of the cons:

• Unpredictable repair prices. MROs will give you an average but the price swings can be great.

• Unpredictable lead times. Nothing is a guarantee.

• Varied customer experience.

• Varied piece part quality.

• Varied piece part pricing. Some MROs inflate piece parts or charge your NE pricing for NS or serviceable.

• You’ll spend more time managing your repair orders.

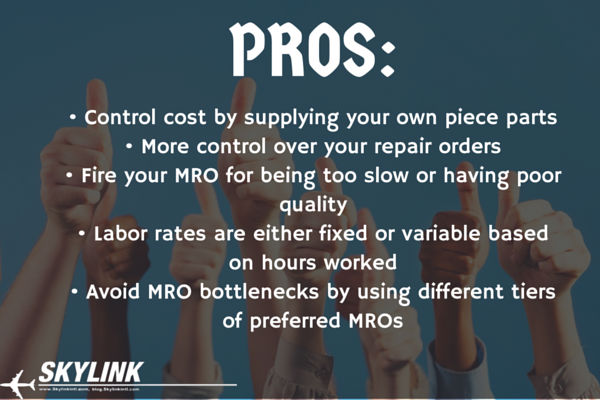

Pros for an aircraft part time and material repair strategy

Just because there’s a few cons doesn’t mean you should avoid them entirely. Time and material repairs can have a great upside, depending on your product or ATA chapter.

Let’s run down a few of the pros:

• You can control the cost by supplying your own piece parts.

• You have more control over your repair orders.

• You can fire your MRO for being too slow or having poor quality.

• The labor rates are either fixed or variable based on hours worked.

• You can avoid MRO bottlenecks by using different tiers of preferred MROs.

Whatever you choose, whether it be fixed rate or time and material, there’s pros and cons of each.

When deciding your repair strategy, sit down and write down your goals. What’s the end result you want to achieve?

If you want more freedom, outsource. If you want more cost predictability, fixed rate. If you want more control, time and material.